})

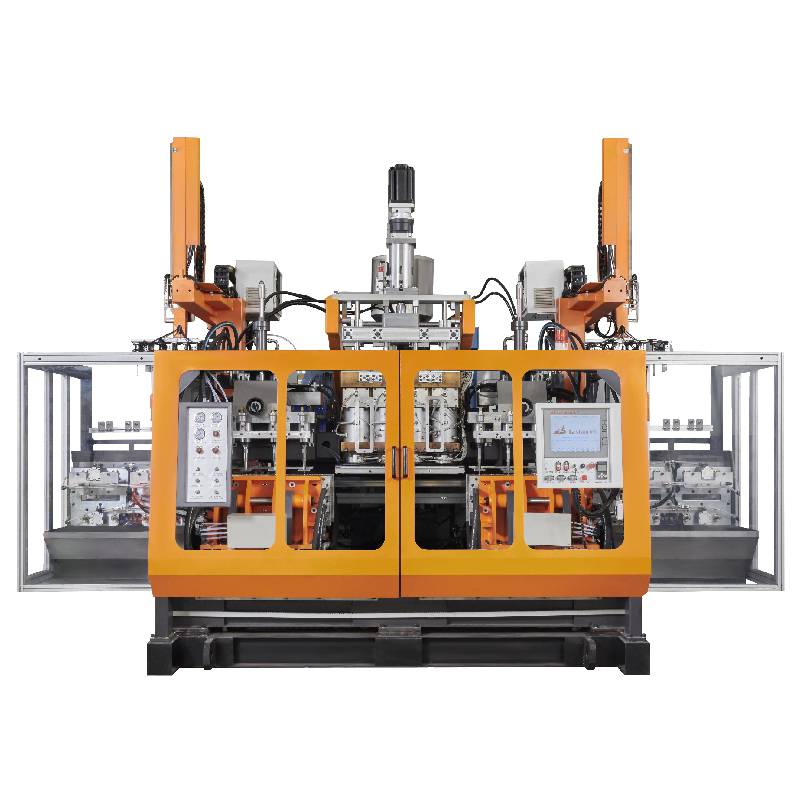

From Blueprint to Production The Making of Leshan Hardcore Blow Molding Machine

How is a highly efficient and reliable blow molding machine born? The answer lies within five defining scenes of dedication at Leshan Intelligent's workshops.

Scene 1: The Blueprint at the Tip of a Pen

Inside the R&D office, quietness buzzes with intense focus. Pens scratch as 3D models on screens are continuously optimized. With expertise as their ruler and innovation as their pen, Leshan's R&D team iterates and calculates meticulously on every design draft. Every structure and each minute detail embodies a profound understanding of the craft, laying the crucial foundation for the machine's performance.

Scene 2: The Battle for Precision in the Workshop

Enter the production floor, where the hum of machine tools plays a symphony of diligence. Automated lines operate in orderly fashion, under the watchful eyes of dedicated craftsmen. From the strict selection and cutting of raw materials to the CNC machining of precision components—milling, drilling, grinding, polishing—every process adheres to established standards. We pursue micron-level precision, obsessed with every dimensional tolerance and surface finish. Here, rough materials are meticulously transformed through multiple stages into reliable core components. Hardcore manufacturing begins with the battle over the slightest margin.

Scene 3: The Artisan's Assembly Puzzle

How do hundreds, even thousands, of parts come together into a complete machine with perfect fit? In the assembly workshop, the skilled hands of master technicians provide the answer. Guided by a belief in rigor, they meticulously align each component—bolt fastening, cable routing, overall calibration—every step is executed with utmost care. Collaboration breathes life into disparate parts; craftsmanship gives the machine its initial form.

Scene 4: Pushing Limits in the Testing Room

This is the final critical gate before delivery. In the testing area, instruments flicker and data streams live. Engineers simulate real production environments, conducting extended continuous run tests. They repeatedly fine-tune blowing speed and molding quality, rigorously validate safety systems, and optimize energy consumption parameters. No minor deviation goes unchecked. Through load testing, temperature control simulations, fault drills, and multiple other verifications, they ensure the equipment reaches its optimal state—stable, efficient, safe, and energy-saving. Every data set is a promise of quality.

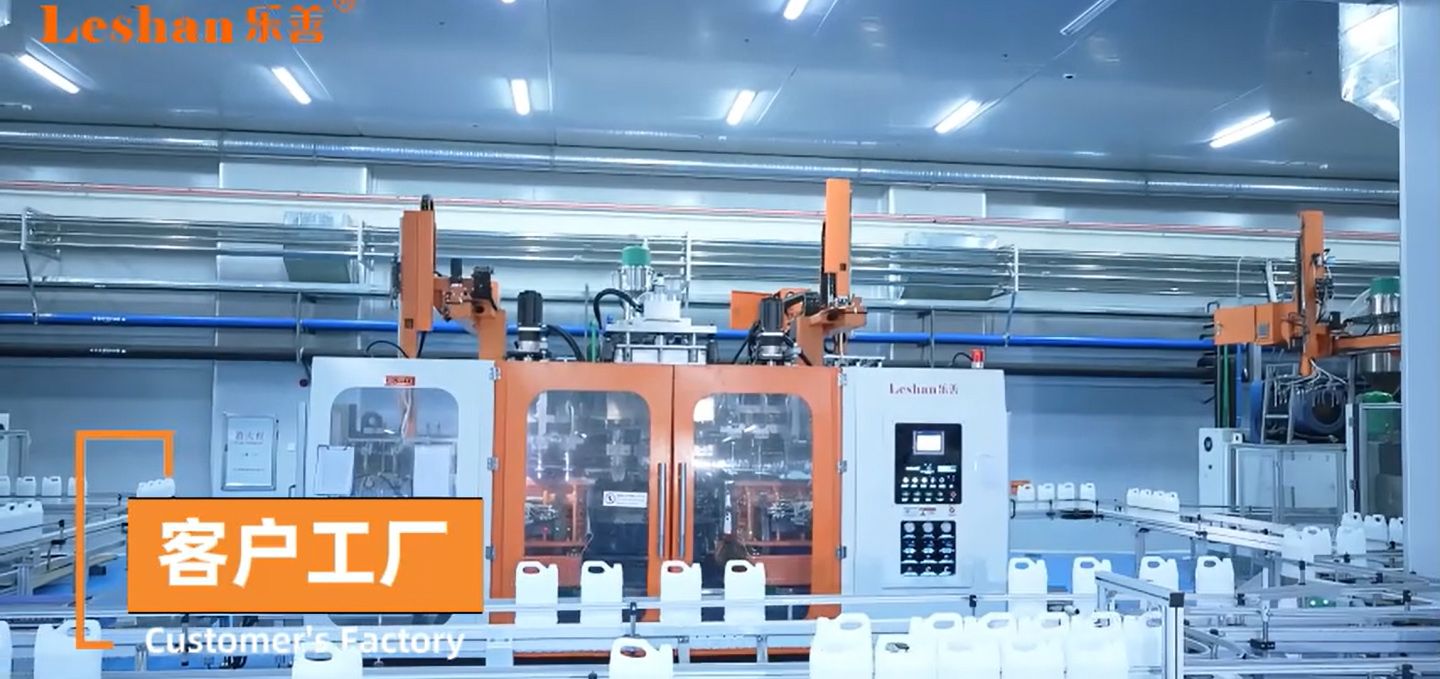

Scene 5: The Smile of Approval on the Client's Floor

When the blow molding machine arrives safely at the client's factory, starts up smoothly, and operates efficiently—all the dedication poured into design, machining, assembly, and testing resonates in this moment. The client's approval and the production line's high efficiency are the ultimate validation of Leshan's craftsmanship. We remain committed to empowering manufacturing through dedication, delivering reliability that earns trust, and partnering with clients on a new journey of industrial upgrading.

From a single blueprint to a high-performance machine in operation.

From a creative idea to a mature, comprehensive solution.

Leshan Intelligent, through relentless dedication and steadfast commitment across the entire chain,

Defines what "craftsmanship in manufacturing" truly means,

And exemplifies the dependable promise of "Intelligent Manufacturing from China."