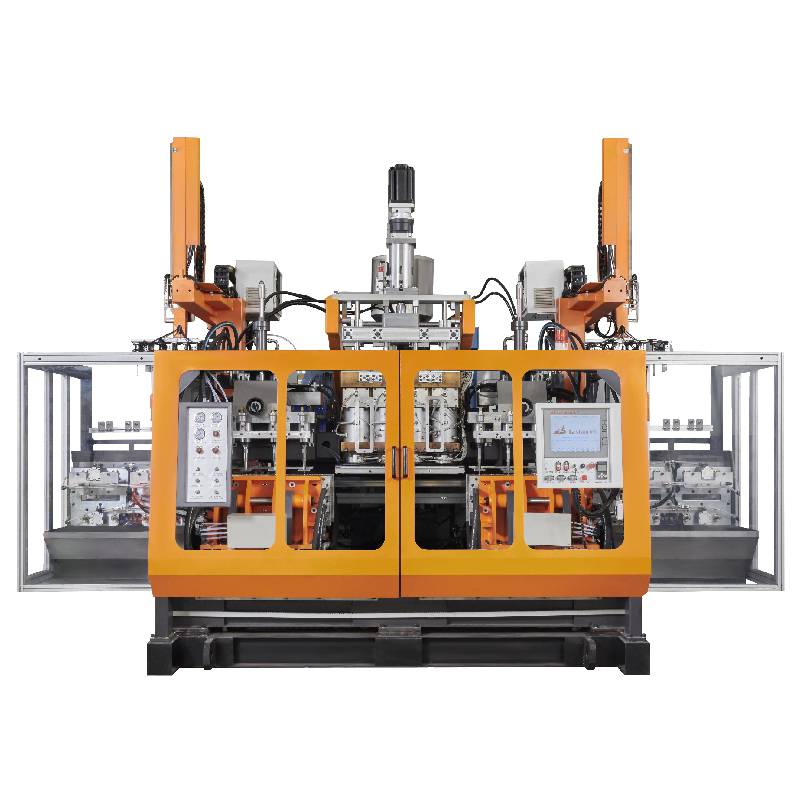

Y Shuttle Mini blow molding machine

Of compact design, Leshan Y shuttle blow molding machine is suitable for producing plastic products of PE/PP/EVA/ABS/K material/ TPU, nylon and other materials below 500ml. All parts of the machine is made by advanced numerical control equipment with high precision. And equipped with imported hydraulic, pneumatic and electrical parts of famous brand, it has stable equipment performance and simple handling.

✓Single/Double Station

✓Single/Double/Triple/Quadruple Head

✓Production Volume:2ml~1L

✓Multi layers: Co-Extrusion 1 Layers

✓Multi cavities: 1~4 cavities

✓Designed for the PE/PP/PETG/PVC/Co-Extrusion material

Category:

Y Shuttle blow molding machine

Tag:

Leshan Y Shuttle Mini blow molding machine

Leshan Y Shuttle Mini Blow Molding Machine

1.Optimized Die Head Flow Path.

2.Three Guide Pillar Tie Bar Design Clamping Unit.

3.Siemens User-Friendly PLC.

Application

Ball

Bath&Beauty

Beverage Package

Car Supplies

Civil Barrel

Jerry Can

Large-volume Tank

Milk Bottle

Toy

Washing Detergent

Other Type

| EXTRUDER | |||

| Extruder Diameter | mm | 45 | 55 |

| Extruder Length/Diameter Ratio | L/D | 21 | 23 |

| Extruder Rotating Speed | r/min | 20-40 | 20-40 |

| Max Extrusion Capacity | kg/h | 14 | 25 |

| Extruder Motor Rated Power | kW | 5.5 | 7.5 |

| Barrel Heating Zone | / | 3 | 3 |

| Barrel Heating Power | kW | 4.5 | 6.2 |

| Cooling Fan Power | kW | 0.04 | 0.08 |

| Die Head | ||

| Cavity number | 1-2 | |

| Center Distance | mm | 70-85 |

| MOLD PLATEN | 2D | |

| Min Clamping Distance Of Mold | mm | 130 |

| Max Clamping Distance Of Mold | mm | 330 |

| Effective Dimension Of Mold Plate | mm W×H | 250×320 |

| Carriage Stroke | (mm) | 400 |

| Clamping Force | kN | 27 |